CONSTRUCTION AND STRUCTURES – II MAJOR ASSIGNMENT

... frames provide support to a steel roof and a variety of forms of external wall construction including: steel sheeting supported by girts, masonry, dado walls, precast concrete panels and tilt-up concrete panels. The steel portal frame provides a one-way rigid/ one-way brace system that holds the bui ...

... frames provide support to a steel roof and a variety of forms of external wall construction including: steel sheeting supported by girts, masonry, dado walls, precast concrete panels and tilt-up concrete panels. The steel portal frame provides a one-way rigid/ one-way brace system that holds the bui ...

O A RIGINAL RTICLE

... Initial funding for the project with a form of tunnel equipment is highly regarded executive. This is due to the increase in the use of machinery, manpower is needed to start providing sufficient funds for tooling and machinery expected. [12]. 4-8 - effects and environmental impacts: According to st ...

... Initial funding for the project with a form of tunnel equipment is highly regarded executive. This is due to the increase in the use of machinery, manpower is needed to start providing sufficient funds for tooling and machinery expected. [12]. 4-8 - effects and environmental impacts: According to st ...

Контрольная работа Английский язык гр. С-413з С-423з

... social conditions at that time. They are now often referred to as high-rise buildings. The city of New York set the skyscraper pattern. Because the ground beneath the city streets is rock, it is solid enough to ...

... social conditions at that time. They are now often referred to as high-rise buildings. The city of New York set the skyscraper pattern. Because the ground beneath the city streets is rock, it is solid enough to ...

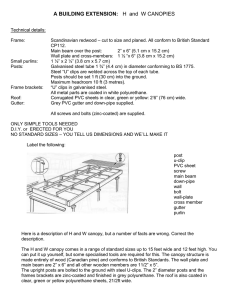

A BUILDING EXTENSION: H and W CANOPIES

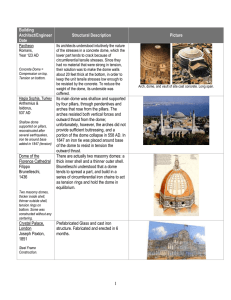

... Concrete is the only major building material that can be delivered to the job site in a plastic state and molded to virtually any form or shape. Concrete can be used to construct a wide variety of structures, such as highways and streets, bridges, dams, large buildings, airport runways, irrigation s ...

... Concrete is the only major building material that can be delivered to the job site in a plastic state and molded to virtually any form or shape. Concrete can be used to construct a wide variety of structures, such as highways and streets, bridges, dams, large buildings, airport runways, irrigation s ...

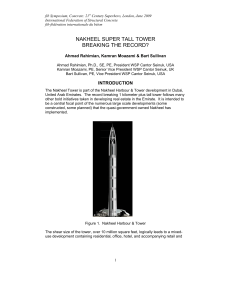

Nakheel #1

... redundancy with alternate load paths. Each truss is supported by an embedded connection to the concrete fin walls. The sixth main element is the floor system which is a conventional steel framed composite concrete on metal deck system. Reducing the overall weight of supertall buildings is always a p ...

... redundancy with alternate load paths. Each truss is supported by an embedded connection to the concrete fin walls. The sixth main element is the floor system which is a conventional steel framed composite concrete on metal deck system. Reducing the overall weight of supertall buildings is always a p ...

Chapter Seven

... • Rigid frame: consists of two columns and a beam or truss • Prefabricated components: made into units and assembled at a factory • Two types of steel construction – Steel skeleton and large-span construction ...

... • Rigid frame: consists of two columns and a beam or truss • Prefabricated components: made into units and assembled at a factory • Two types of steel construction – Steel skeleton and large-span construction ...

Building - ARE Forum

... example, accentuates its structure. The piers between the windows form strong vertical lines that draw the eye upward to the dominant cornice. Yet, despite the technological advancements that made the skyscraper possible (such as structural steel and elevators), Sullivan strove to connect it with th ...

... example, accentuates its structure. The piers between the windows form strong vertical lines that draw the eye upward to the dominant cornice. Yet, despite the technological advancements that made the skyscraper possible (such as structural steel and elevators), Sullivan strove to connect it with th ...

Rieder Smart Elements Press Release Mühlenweg 22 January 2007

... transitions between the different levels guide the visitor through an exploration of the world of wine. From the sales level on the ground floor, the path leads via the lower mezzanine up to the village bar with sitting steps and a new interpretation of the bow window that is a popular feature in So ...

... transitions between the different levels guide the visitor through an exploration of the world of wine. From the sales level on the ground floor, the path leads via the lower mezzanine up to the village bar with sitting steps and a new interpretation of the bow window that is a popular feature in So ...

Rahal Volvo-Jaguar.qxd

... and service areas on the main floor. Shared offices for service representatives are located between the two customer service areas. A lounge and retail display is provided at each dealership in the customer service areas. Parts and service departments are located towards the rear of the building on ...

... and service areas on the main floor. Shared offices for service representatives are located between the two customer service areas. A lounge and retail display is provided at each dealership in the customer service areas. Parts and service departments are located towards the rear of the building on ...

Precast concrete

Precast concrete is a construction product produced by casting concrete in a reusable mold or ""form"" which is then cured in a controlled environment, transported to the construction site and lifted into place. In contrast, standard concrete is poured into site-specific forms and cured on site. Precast stone is distinguished from precast concrete by using a fine aggregate in the mixture, so the final product approaches the appearance of naturally occurring rock or stone.By producing precast concrete in a controlled environment (typically referred to as a precast plant), the precast concrete is afforded the opportunity to properly cure and be closely monitored by plant employees. Utilizing a Precast Concrete system offers many potential advantages over site casting of concrete. The production process for Precast Concrete is performed on ground level, which helps with safety throughout a project. There is a greater control of the quality of materials and workmanship in a precast plant rather than on a construction site. Financially, the forms used in a precast plant may be reused hundreds to thousands of times before they have to be replaced, which allow cost of formwork per unit to be lower than for site-cast production.Many states across the United States require a precast plant to be certified by either the Architectural Precast Association (APA), National Precast Concrete Association (NPCA) or Precast Prestressed Concrete Institute (PCI) for a precast producer to supply their product to a construction site sponsored by State and Federal DOTs.There are many different types of precast concrete forming systems for architectural applications, differing in size, function, and cost. Precast architectural panels are also used to clad all or part of a building facade free-standing walls used for landscaping, soundproofing, and security walls, and some can be Prestressed concrete structural elements. Stormwater drainage, water and sewage pipes, and tunnels make use of precast concrete units. The New South Wales Government Railways made extensive use of precast concrete construction for its stations and similar buildings. Between 1917 and 1932, they erected 145 such buildings. Beyond cladding panels and structural elements, entire buildings can be assembled from precast concrete. Precast assembly enables fast completion of commercial shops and offices with minimal labor. For example, the Jim Bridger Building in Williston, North Dakota, was precast in Minnesota with air, electrical, water, and fiber utilities preinstalled into the building panels. The panels were transported over 800 miles to the Bakken oilfields, and the commercial building was assembled by 3 workers in minimal time. The building houses over 40,000 square feet of shops and offices. Virtually the entire building was fabricated in Minnesota.To complete the look of the four precast wall panel types — sandwich, plastered sandwich, inner layer, and cladding panels — there are many different possibilities for the surface. The cement can be white or grey, and the color and size of the aggregate make a difference. Different colors, pigments, and paints can be added. The shape and surface of the precast concrete molds have an effect on the look: the mold can be made of timber, steel, plastic, rubber, or fiberglass, each material giving a unique finish.