* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download ELECTRIC DRIVES

Survey

Document related concepts

Alternating current wikipedia , lookup

History of electric power transmission wikipedia , lookup

Power engineering wikipedia , lookup

Electric locomotive wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Electric vehicle wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

Electric machine wikipedia , lookup

General Electric wikipedia , lookup

Electric motor wikipedia , lookup

Stepper motor wikipedia , lookup

Dynamometer wikipedia , lookup

Induction motor wikipedia , lookup

Transcript

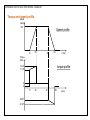

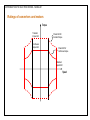

ELECTRIC DRIVES INTRODUCTION TO ELECTRIC DRIVES MODULE 1 Dr. Nik Rumzi Nik Idris Dept. of Energy Conversion, UTM 2013 INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Electrical Drives Drives are systems employed for motion control Require prime movers Drives that employ electric motors as prime movers are known as Electrical Drives INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Electrical Drives • About 50% of electrical energy used for drives • Can be either used for fixed speed or variable speed • • 75% - constant speed, 25% variable speed (expanding) MEP 1523 will be covering variable speed drives INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Example on VSD application Variable Speed Drives Constant speed valve Supply Power In motor pump Power out Power loss Mainly in valve INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Example on VSD application Variable Speed Drives Constant speed valve Supply Power In motor Supply pump PEC Power out Power loss Mainly in valve Power In motor pump Power out Power loss INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Example on VSD application Variable Speed Drives Constant speed valve Supply Power In motor Supply pump PEC Power out Power loss Mainly in valve Power In motor pump Power out Power loss INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Conventional electric drives (variable speed) • Bulky • Inefficient • inflexible INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Modern electric drives (With power electronic converters) • Small • Efficient • Flexible INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Modern electric drives Machine design Speed sensorless Machine Theory Utility interface Renewable energy Non-linear control Real-time control DSP application PFC Speed sensorless Power electronic converters • Inter-disciplinary • Several research area • Expanding INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Components in electric drives Motors • DC motors - permanent magnet – wound field • AC motors – induction, synchronous (IPMSM, SMPSM), brushless DC • Applications, cost, environment • Natural speed-torque characteristic is not compatible with load requirements Power sources • DC – batteries, fuel cell, photovoltaic - unregulated • AC – Single- three- phase utility, wind generator - unregulated Power processor • To provide a regulated power supply • Combination of power electronic converters • More efficient • Flexible • Compact • AC-DC DC-DC DC-AC AC-AC INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Components in electric drives Control unit • Complexity depends on performance requirement • analog- noisy, inflexible, ideally has infinite bandwidth. • digital – immune to noise, configurable, bandwidth is smaller than the analog controller’s • DSP/microprocessor – flexible, lower bandwidth - DSPs perform faster operation than microprocessors (multiplication in single cycle), can perform complex estimations • Electrical isolation between control circuit and power circuit is needed: • Malfuction in power circuit may damage control circuit • Safety for the operator • Avoid conduction of harmonic to control circuit INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Components in electric drives Sensors • Sensors (voltage, current, speed or torque) is normally required for closed-loop operation or protection • Electrical isolation between sensors and control circuit is needed for the reasons previously explained • The term ‘sensorless drives’ is normally referred to the drive system where the speed is estimated rather than measured. INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Overview of AC and DC drives Extracted from Boldea & Nasar INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Overview of AC and DC drives DC motors: Regular maintenance, heavy, expensive, speed limit Easy control, decouple control of torque and flux AC motors: Less maintenance, light, less expensive, high speed Coupling between torque and flux – variable spatial angle between rotor and stator flux INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Overview of AC and DC drives Before semiconductor devices were introduced (<1950) • AC motors for fixed speed applications • DC motors for variable speed applications After semiconductor devices were introduced (1950s) • Variable frequency sources available – AC motors in variable speed applications • Coupling between flux and torque control • Application limited to medium performance applications – fans, blowers, compressors – scalar control • High performance applications dominated by DC motors – tractions, elevators, servos, etc INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Overview of AC and DC drives After semiconductor devices were introduced (1950s) INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Overview of AC and DC drives After vector control drives were introduced (1980s) • AC motors used in high performance applications – elevators, tractions, servos • AC motors favorable than DC motors – however control is complex hence expensive • Cost of microprocessor/semiconductors decreasing –predicted 30 years ago AC motors would take over DC motors INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Classification of IM drives IEEE Transactions on Industrial Electronics, 2004. (Buja, Kamierkowski, “Direct torque control of PWM inverter-fed AC motors - a survey”, INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Elementary principles of mechanics v x Newton’s law M Fm Ff Fm Ff dMv dt Linear motion, constant M dv d2 x Fm Ff M M 2 Ma dt dt • • First order differential equation for speed Second order differential equation for displacement INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Elementary principles of mechanics Rotational motion - Normally is the case for electrical drives Tl Te Tl Te , m dJm dt J With constant J, dm d 2 Te Tl J J 2 dt dt • • First order differential equation for angular frequency (or velocity) Second order differential equation for angle (or position) INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Elementary principles of mechanics For constant J, dm dt dm dt dm dt Torque dynamic – present during speed transient Angular acceleration Larger net torque and smaller J gives faster acceleration speed (rad/s) 200 100 0 -100 -200 0.19 0.2 0.21 0.22 0.23 0.24 0.25 0.2 0.21 0.22 0.23 0.24 0.25 20 torque (Nm) J Te Tl J 15 10 5 0 0.19 INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Elementary principles of mechanics A drive system that require fast acceleration must have • large motor torque capability • small overall moment of inertia As the motor speed increases, the kinetic energy also increases. During deceleration, the dynamic torque changes its sign and thus helps motor to maintain the speed. This energy is extracted from the stored kinetic energy: J is purposely increased to do this job ! INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Elementary principles of mechanics Combination of rotational and translational motions Fe Fl M r Te, r Tl v Fe Fl M dv dt Te Tl r 2M Te = r(Fe), d dt r2M - Equivalent moment inertia of the linearly moving mass Tl = r(Fl), v =r INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Elementary principles of mechanics – effect of gearing Motors designed for high speed are smaller in size and volume Low speed applications use gear to utilize high speed motors Motor Te m1 m n1 Load 1, Tl1 J2 m2 J1 n2 Load 2, Tl2 INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Elementary principles of mechanics – effect of gearing m Motor Te m1 Load 1, Tl1 n1 m2 J1 Motor Te m n2 J2 Load 2, Tl2 J equ J1 a 22 J 2 Equivalent Load , Tlequ Tlequ = Tl1 + a2Tl2 Jequ a2 = n1/n2=2/1 INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Motor steady state torque-speed characteristic (natural characteristic) SPEED Synchronous mch Induction mch Separately / shunt DC mch Series DC TORQUE By using power electronic converters, the motor characteristic can be change at will INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Load steady state torque-speed characteristic Frictional torque (passive load) SPEED T~ C T~ 2 T~ • Exist in all motor-load drive system simultaneously • In most cases, only one or two are dominating • Exists when there is motion TORQUE Coulomb friction Viscous friction Friction due to turbulent flow INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Load steady state torque-speed characteristic Constant torque, e.g. gravitational torque (active load) SPEED Gravitational torque Vehicle drive Te TORQUE TL gM FL TL = rFL = r g M sin INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Load steady state torque-speed characteristic Hoist drive Speed Torque Gravitational torque INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Load and motor steady state torque At constant speed, Te= Tl Steady state speed is at point of intersection between Te and Tl of the steady state torque characteristics Te Torque Tl Steady state speed r3 r1r r2 Speed INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Torque and speed profile speed (rad/s) Speed profile 100 10 25 The system is described by: J = 0.01 kg-m2, 45 60 t (ms) Te – Tload = J(d/dt) + B B = 0.01 Nm/rads-1 and Tload = 5 Nm. What is the torque profile (torque needed to be produced) ? INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Torque and speed profile speed (rad/s) d Te J B Tl dt 100 10 25 45 60 t (ms) 0 < t <10 ms Te = 0.01(0) + 0.01(0) + 5 Nm = 5 Nm 10ms < t <25 ms Te = 0.01(100/0.015) +0.01(-66.67 + 6666.67t) + 5 = (71 + 66.67t) Nm 25ms < t< 45ms Te = 0.01(0) + 0.01(100) + 5 = 6 Nm 45ms < t < 60ms Te = 0.01(-100/0.015) + 0.01(400 -6666.67t) + 5 = -57.67 – 66.67t INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Torque and speed profile speed (rad/s) 100 Speed profile 10 25 45 60 t (ms) Torque (Nm) 72.67 71.67 torque profile 6 5 10 -60.67 -61.67 25 45 60 t (ms) INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Torque and speed profile Torque (Nm) 70 J = 0.001 kg-m2, B = 0.1 Nm/rads-1 and Tload = 5 Nm. 6 10 25 45 60 t (ms) -65 For the same system and with the motor torque profile given above, what would be the speed profile? INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Thermal considerations Unavoidable power losses causes temperature increase Insulation used in the windings are classified based on the temperature it can withstand. Motors must be operated within the allowable maximum temperature Sources of power losses (hence temperature increase): - Conductor heat losses (i2R) - Core losses – hysteresis and eddy current - Friction losses – bearings, brush windage INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Thermal considerations Electrical machines can be overloaded as long their temperature does not exceed the temperature limit Accurate prediction of temperature distribution in machines is complex – hetrogeneous materials, complex geometrical shapes Simplified assuming machine as homogeneous body Ambient temperature, To p1 Input heat power (losses) Thermal capacity, C (Ws/oC) Surface A, (m2) Surface temperature, T (oC) p2 Emitted heat power (convection) INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Thermal considerations Power balance: C dT p1 p 2 dt Heat transfer by convection: , where is the coefficient of heat transfer p 2 A(T To ) Which gives: dT A p T 1 dt C C With T(0) = 0 and p1 = ph = constant , T ph 1 e t / A , where C A INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Thermal considerations ph A T T ph 1 e t / A Heating transient T t T T(0) e t / T ( 0) Cooling transient t INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Thermal considerations The duration of overloading depends on the modes of operation: Continuous duty Load torque is constant over extended Continuous duty period multiple Short time intermittent duty Steady state temperature reached Periodic intermittent duty Nominal output power chosen equals or exceeds continuous load p1n A T Losses due to continuous load p1n t INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Thermal considerations Short time intermittent duty Operation considerably less than time constant, Motor allowed to cool before next cycle Motor can be overloaded until maximum temperature reached INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Thermal considerations Short time intermittent duty p1s p1 p1n p 1s A T p1n A Tmax t1 t INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Thermal considerations T T p1n A Tmax t1 pp11nn p1ps 1s1 1eet1 / t1 / A A Short time intermittent duty p1s 1 e t / A p1s 1 t1 / p1n 1 e t1 t INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Thermal considerations Periodic intermittent duty Load cycles are repeated periodically Motors are not allowed to completely cooled Fluctuations in temperature until steady state temperature is reached INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Thermal considerations Periodic intermittent duty p1 heating coolling heating coolling heating coolling t INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Thermal considerations Periodic intermittent duty Example of a simple case – p1 rectangular periodic pattern pn = 100kW, nominal power M = 800kg = 0.92, nominal efficiency T= 50oC, steady state temperature rise due to pn 1 p1 pn 1 9kW Also, A p1 9000 180 W / o C T 50 If we assume motor is solid iron of specific heat cFE=0.48 kWs/kgoC, thermal capacity C is given by C = cFE M = 0.48 (800) = 384 kWs/oC Finally , thermal time constant = 384000/180 = 35 minutes INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Thermal considerations Periodic intermittent duty Example of a simple case – p1 rectangular periodic pattern For a duty cycle of 30% (period of 20 mins), heat losses of twice the nominal, 35 30 25 20 15 10 5 0 0 0.5 1 1.5 2 2.5 4 x 10 INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Torque-speed quadrant of operation T -ve +ve Pm -ve 2 1 T +ve +ve Pm +ve T 3 T -ve -ve Pm +ve 4 T +ve -ve Pm -ve INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 4-quadrant operation m Te m • Direction of positive torque will produce positive (forward) speed Quadrant 2 Forward braking Quadrant 1 Forward motoring Quadrant 3 Reverse motoring Quadrant 4 Reverse braking Te m • Direction of positive (forward) speed is arbitrary chosen Te T Te m INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Ratings of converters and motors Torque Transient torque limit Continuous torque limit Power limit for transient torque Power limit for continuous torque Maximum speed limit Speed INTRODUCTION TO ELECTRIC DRIVES - MODULE 1 Steady-state stability