* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download EVSTF09-32-TF2-04

Buck converter wikipedia , lookup

War of the currents wikipedia , lookup

Electromagnetic compatibility wikipedia , lookup

Skin effect wikipedia , lookup

Power engineering wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Current source wikipedia , lookup

Three-phase electric power wikipedia , lookup

Electrical engineering wikipedia , lookup

Voltage optimisation wikipedia , lookup

Electrification wikipedia , lookup

Electrical substation wikipedia , lookup

Electric machine wikipedia , lookup

History of electromagnetic theory wikipedia , lookup

Ground loop (electricity) wikipedia , lookup

Electrician wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electric motorsport wikipedia , lookup

Electric vehicle conversion wikipedia , lookup

Rectiverter wikipedia , lookup

Portable appliance testing wikipedia , lookup

Opto-isolator wikipedia , lookup

Surge protector wikipedia , lookup

Stray voltage wikipedia , lookup

Alternating current wikipedia , lookup

Mains electricity wikipedia , lookup

National Electrical Code wikipedia , lookup

Ground (electricity) wikipedia , lookup

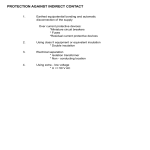

Residual-current device wikipedia , lookup

EVSTF09-32-TF2-04 Personnel protection during charging 2016/9/13, T.Miki / Toyota During charging, personnel protection against electrical shock is ensured mainly by EV supply equipment (charger) and/or fixed installation (electric power supply network) with the basic protection in an EV, similar to the case for a washing machine. When an EV is connected to a grounded AC supply network (almost all AC supply networks are grounded at one pole) by an EV supply equipment, the vehicle electrical chassis is connected to the earth/ground through earthing/grounding conductor. The insulation resistance between the high voltage live parts and the vehicle electrical chassis is almost zero (earthing/grounding resistance) in this case. Protection against electrical shock during charging is achieved by the combination of - basic insulation (protection against direct contact with high voltage live parts), and - equipotential bonding (earthig/grounding in this case) - in addition, automatic disconnection of supply operated by the fault current that disconnects one or more of the line conductors (e.g. RCD/ CCID) is provided EV supply equipment is provided with - earthing/grounding conductor between the electrical chassis of a vehicle and the earth/ground - earthing/grounding continuity monitor (except mode 1 charging, which is not allowed in US) - RCD/CCID (either in EV supply equipment or fixed electrical installation, or both) for personnel protection according to the relevant standards/regulations (e.g. IEC 61851, SAE J1772, UL 2231, GB/T 18487) If the electrical insulation is lost during charging, the leakage current flows through earthing/grounding conductor to the earth/ground. The current that flows between the vehicle electrical chassis and the earth/ground is limited. In addition, the RCD/CCID opens the circuit to interrupt the supply of energy within specified time if the residual/differential current (= leakage current) reaches or exceeds the specified safety threshold due to the fault/deterioration of the electrical insulation. The characteristics of the RCD/ CCID are specified in the relevant standards as well as according to a national electrical code of each country.) Grid RCD/ CCID Fault current AC/DC Insulation fault! Earth/ground Electrical chassis The residual current at 500 Ω/VAC isolation resistance between the high voltage bus and the electrical chassis when the charger coupler is disconnected is sufficiently lower than the residual current to trip the RCD/CCID. The same requirement as proposed by OICA has been already adopted in ISO 17409 as the consensus of IEC experts and ISO experts. Current requirement of 1 MΩ came from IEC 61851-1 that exists more than 15 years ago. At that time, there was some discussion that the European Low Voltage Directive to cover the EV during charging among electrical installation experts. Automobile industry picked the IEC requirement up without deep consideration on its rationale, to instantly show them that automobile regulation already covers the safety requirement during charging. As of now, the rationale behind the IEC requirement is unclear … Note: residual current device (RCD) mechanical switching device designed to make, carry and break currents under normal service conditions and to cause the opening of the contacts when the residual current attains a given value under specified conditions Note 1 to entry: A residual current device can be a combination of various separate elements designed to detect and evaluate the residual current and to make and break current. [Source: IEC 61851-1, IEV 442-05-02] charging circuit interrupting device (CCID) A device that continuously monitors the differential current among all of the current-carrying line conductors in a grounded system and rapidly interrupts the circuit under conditions where the differential current exceeds the rated Measurement Indication Unit (MIU) value of a charging circuit interrupting device. The device is identified by the letters CCID followed by the differential trip current rating of either 5 or 20 indicating the tripping rating in MIU. [Source: UL 2231-1] Bibliography IEC 61851-1: Electric Vehicle Conductive Charging System – Part 1: General requirements IEC 62752: In-Cable Control and Protection Device for mode 2 charging of electric road vehicles (IC-CPD) IEC 60364-7-722: Requirements for special installations or locations – Supplies for electric vehicles ISO 17409: Electrically propelled road vehicles – Connection to an external electric power supply — Safety requirements SAE J1772: SAE Electric Vehicle and Plug in Hybrid Electric Vehicle Conductive Charge Coupler UL 2231-1: Personnel Protection Systems for Electric Vehicle Supply Circuits: General Requirements UL 2231-2: Personnel Protection Systems for Electric Vehicle Supply Circuits: Particular Requirements for Protection Devices for Use in Charging Systems GB/T 18487.1: 电动汽车传导充电系统 第 1 部分:通用要求 (Electric vehicle conductive charging system Part 1: General requirements )