* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

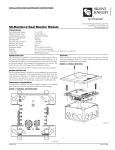

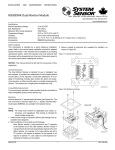

Download Wiring Notes Please observe the following wiring notes while

Electrician wikipedia , lookup

Electrification wikipedia , lookup

Buck converter wikipedia , lookup

Skin effect wikipedia , lookup

Rotary encoder wikipedia , lookup

Loading coil wikipedia , lookup

Opto-isolator wikipedia , lookup

Power over Ethernet wikipedia , lookup

Power engineering wikipedia , lookup

History of electric power transmission wikipedia , lookup

Ground (electricity) wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Stepper motor wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Three-phase electric power wikipedia , lookup

Rectiverter wikipedia , lookup

Ground loop (electricity) wikipedia , lookup

Overhead line wikipedia , lookup

Stray voltage wikipedia , lookup

Single-wire earth return wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Electrical connector wikipedia , lookup

Voltage optimisation wikipedia , lookup

Alternating current wikipedia , lookup

Mains electricity wikipedia , lookup

Telecommunications engineering wikipedia , lookup

National Electrical Code wikipedia , lookup

Lexium 23D Wiring Notes 5. Installation Please observe the following wiring notes while performing wiring and touching any electrical connections on the servo drive or servo motor. 1. Ensure to check if the power supply and wiring of the "power" terminals (R, S, T, L1, L2, U, V, W) is correct. 2. Please use shielded twisted-pair cables for wiring to prevent voltage coupling and eliminate electrical noise and interference. 3. As a residual hazardous voltage may remain inside the drive, please do not immediately touch any of the "power" terminals (R, S, T, L1, L2, U, V, & W) and/or the cables connected to them after the power has been turned off and the charge LED is lit. (Please refer to the Safety Precautions chapter 2 "Before you begin - safety information"). 4. The cables connected to R, S, T and U, V, W terminals should be placed in separate conduits from the encoder or other signal cables. Separate them by at least 30cm (11.8 inches). 5. If the encoder cable (CN2) is too short, please use a twisted-shield signal wire with grounding conductor. The wire length should be 20m (65.62ft.) or less. For lengths greater than 20m (65.62ft.), the wire gauge should be doubled in order to lessen any signal attenuation. 6. As for motor cable selection, please use the 600V PTFE wire and the wire length should be less than 98.4ft. (30m). If the wiring distance is longer than 30m (98.4ft.), please choose the adequate wire size according to the voltage. 7. The shield of shielded twisted-pair cables should be connected to the SHIELD end (terminal marked ) of the servo drive. 8. For the connectors and cables specifications. AC servo drive 73