* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Ignition Systems - QSSTransportationTechnology

Three-phase electric power wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Electric machine wikipedia , lookup

Current source wikipedia , lookup

Electric battery wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electrical substation wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Opto-isolator wikipedia , lookup

Rechargeable battery wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Transformer types wikipedia , lookup

Electrical ballast wikipedia , lookup

Voltage optimisation wikipedia , lookup

Buck converter wikipedia , lookup

Voltage regulator wikipedia , lookup

Surge protector wikipedia , lookup

Stray voltage wikipedia , lookup

Rectiverter wikipedia , lookup

Alternating current wikipedia , lookup

Spark-gap transmitter wikipedia , lookup

Mains electricity wikipedia , lookup

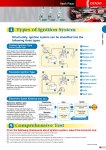

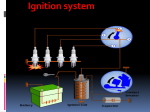

Ignition Systems The purpose of the ignition system is to provide a spark at the correct time in the combustion chamber to ignite the air-fuel mixture. Spark must occur 8-26 ° before TDC in order to have combustion 10 ° after TDC for maximum power and least emissions. Ignition System Types Magneto: Used on small engines such as lawnmowers and chainsaws (no battery needed). The primary voltage comes from the magneto (flywheel magnets), and is then further amplified to jump across the spark plug gap. The spark is timed by the use of mechanical breaker points. Capacitor Discharge: Similar to magneto ignition without the use of breaker points. The points are replaced with solid state (non moving) components which are much more reliable, give a hotter spark and don’t require periodic adjustment. Battery Ignition System: Primary voltage comes from a battery and is then further amplified. Battery type is the only type used for automotive applications. Battery ignition systems can be either the point type or the electronic type. Magneto Ignition The idea behind a magneto is simple. It is basically an electrical generator that has been tuned to create a periodic high-voltage pulse rather than continuous current. An electrical generator (or a magneto) is the reverse of an electromagnet. In an electromagnet there is a coil of wire around an iron bar (the armature). When you apply current to the electromagnet's coil (e.g. with a battery), the coil creates a magnetic field in the armature. In a generator, you reverse the process. You move a magnet past the armature to create electric current in the coil. A magneto consists of five parts: An armature. The armature is shaped like a capital "U". The two ends of the U point toward the flywheel. A primary coil of perhaps 200 turns of thick wire wrapped around one leg of the U A secondary coil of perhaps 20,000 turns of very thin wire wrapped around the primary coil A simple electronic control unit that commonly goes by the name "electronic ignition" (or a set of breaker points and a capacitor) A pair of strong permanent magnets embedded in the engine's flywheel. When the magnets fly past the U-shaped armature, they induce a magnetic field in the armature. This field induces some small amount of current in the primary and secondary coil. What we need, however, is extremely high voltage. Therefore, as the magnetic field in the armature reaches its maximum, a switch in the electronic control unit opens. This switch breaks the flow of current through the primary coil and causes a voltage spike (of perhaps 200 volts). The secondary coil, having 100 times more turns than the primary coil, amplifies this voltage to approximately 20,000 volts, and this voltage feeds to the spark plug. (Info from howstuffworks.com) Battery Ignition System (point type) Ignition System Parts Battery: Supplies 12V to ignition primary circuit. Ignition Switch: Ensures power only supplied when starting or running engine. Ignition Coil: A transformer which uses electromagnetic induction principles to increase voltage from 12V to 40,000V. The voltage is increased whenever the primary current stops (points open) Breaker Points: Operated by distributor cam. The points switch ignition primary circuit on and off for each cylinder that fires. Current flows through primary circuit when points are closed. (at 100 kph a 6 cylinder engine must produce 9000 sparks per minute) Condenser: Absorbs and stores electrical energy each time the points open. This reduces arcing in points and makes them last longer. Distributor: Receives and distributes secondary voltage to the appropriate cylinder through the firing order. High Tension Wires: Well insulated wires which can with stand the high secondary voltage. Spark Plug: Provides the gap for high secondary voltage to jump across and ignite the air fuel mixture. Available in variety of heat ranges and must be matched to the engine. Use colder plug for hot engine (lawnmower), and a hotter plug for cold engine (snow blower). If spark plugs get too hot, the electrodes don’t last as long, and if too cold then they foul with carbon. Some plugs are also available in platinum and iridium tip to make them last longer. (160,000 km) Battery Ignition System (electronic type)Transistor: Electronic switch used to replace breaker points. (transistors have no moving parts) Reluctor: Reluctor is used to switch the transistor on and off at the correct time. Advantages of electronic ignition are: Less moving parts and less maintenance Higher secondary voltages than with point type ignition Much more reliable Battery Ignition System (distributorless) Distributorless ignition systems are the best system possible for the following reasons: No moving parts Simple layout with fewest number of parts Very high secondary voltages Any number of coils, sometimes one per cylinder