* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download CLUSTER Engineering and Technical CONCENTRATION Industrial

Induction motor wikipedia , lookup

Opto-isolator wikipedia , lookup

Three-phase electric power wikipedia , lookup

Telecommunications engineering wikipedia , lookup

Surge protector wikipedia , lookup

Electromagnetic compatibility wikipedia , lookup

Distribution management system wikipedia , lookup

Electrification wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Electrical substation wikipedia , lookup

Flexible electronics wikipedia , lookup

Voltage optimisation wikipedia , lookup

Ground (electricity) wikipedia , lookup

Stray voltage wikipedia , lookup

Earthing system wikipedia , lookup

Power engineering wikipedia , lookup

History of electric power transmission wikipedia , lookup

Portable appliance testing wikipedia , lookup

Electrician wikipedia , lookup

Electrical wiring wikipedia , lookup

Alternating current wikipedia , lookup

Electrical engineering wikipedia , lookup

Electronic engineering wikipedia , lookup

Mains electricity wikipedia , lookup

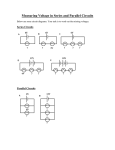

CLUSTER Engineering and Technical CONCENTRATION Industrial Electrical Control Systems WVEIS CODE ET 1895 ONET CODES and OCCUPATIONS ONET: 47-2111.00 Electricians ONET: 49-2094.00 Electrical and Electronics Repairers, Commercial and Industrial Equipment ONET: 17-3023.01 Electronics Engineering Technicians ONET: 17-3026.00 Industrial Engineering Technician ONET: 51-2022.00 Electrical and Electronic Equipment Assemblers ONET: 49-2092.00 Electric Motor, Power Tool and Related Repairs Sample of job titles upon completion of the concentration: Electronics Technician, Test Technician, Engineering Aide, Repair Technician, Service Technician, Maintenance Electrician, Production Staff Worker, Assembly Worker, Electronic Assembler, Final Motor Assembler. REQUIRED COURSES WVEIS Code 1763 1807 1771 1765 Course Fundamentals of Electricity Industrial Electricity Rotating Devices and Control Circuitry Industrial and Commercial Wiring SKILL SETS Career Preparation Skills Safety Leadership Development Customer and Personal Service Electrical Safety Electrical Math Concepts Basic Circuits Electrical Basics Control Circuitry Motor Controls Conduit and Raceways Commercial Load Calculations And Configurations 1 Skill set Career Preparation Skills, Safety, Leadership Development and Customer and Personal Service should be integrated throughout the concentration as remaining skill sets are delivered. Skill Set Knowledge Objectives Career Preparation Skills Students will demonstrate knowledge of Performance Objectives Students will Skill Set Knowledge Objectives career paths. goal development and achievement. attitudes and work habits that support career retention and advancement. communication in varied contexts. relate skills and abilities to possible career pathways. explain methods of goal development. discuss methods of time management and task coordination. practice professionalism in punctuality, appropriate dress, task completion, etc. investigate methods of supervision such as giving and receiving feedback and instruction. develop and present a statement of their personal work ethic beliefs. prepare an application, cover letter, resume and thank you letter. create a personal portfolio for use when applying for employment. practice simulated job interviews. Safety Students will demonstrate knowledge of Performance Objectives performing tasks in a safe manner. safety procedures required when using hazardous materials. proper use of tools and equipment associated with industrial electrical equipment. proper use of shop equipment. Students will define personal and environmental safety on the job. demonstrate the proper use of shop equipment and tools. properly select, use, and dispose of shop chemicals. explain the purpose and requirements of MSDS. define NIOSH recommendations for evaluating and controlling hazards. explain and demonstrate the proper lock-out and tag-out procedures. explain the purpose and operation of Ground Fault Circuit Interrupter. select personal protection equipment (PPE); inspect to insure fit, operation, and maintenance. analyze possible causes and effects of electrical shock. identify regulatory agencies and standards organizations related to industrial technology. 2 Skill Set Knowledge Objectives Performance Objectives Leadership Development Students will demonstrate knowledge of public speaking. parliamentary law. leadership concepts. characteristics of effective teams and organizations. Students will Skill Set develop and deliver speeches. participate in meetings using parliamentary procedure. attend leadership conferences or training. (local, state, national) volunteer in community service opportunities. participate in career development events. Customer and Personal Service Knowledge Objectives Students will demonstrate knowledge of Performance Objectives customer needs assessment. quality standards of service. assessing customer satisfaction. Students will consult with customers, supervisors, or engineers to plan layout of equipment or to resolve problems in system operation or maintenance. plan work procedures, using charts, technical manuals, and experience. follow up; keep customer/client informed about parts and the repair process. test and adjust repaired systems to meet manufacturers performance specifications. advise management regarding customer satisfaction, product performance, or suggestions for product improvement. maintain cleanliness of work area. 3 Fundamentals of Electricity Skill Set Knowledge Objectives Performance Objectives WVEIS 1763 Electrical Safety Students will demonstrate knowledge of basic electrical safety. Students will Skill Set Knowledge Objectives Students will demonstrate knowledge of Performance Objectives accurate measurement practices. algebraic computations. critical thinking skills. Students will Skill Set Knowledge Objectives describe the effect of current on a human body. explain what to do for victims of electrical shock describe typical shock hazards in industry. identify various types of safety devices used with electricity. list general safety precautions when working with electricity. list and describe the safe use of basic hand tools and power tools used in the field of electricity. demonstrate and use properly an ammeter, ohmmeter and a voltmeter. explain the difference between power and control circuits. define electric charge and electric current. differentiate between insulators, conductors and semi-conductors. define current, voltage and resistance. explain the theory of ohm’s law. utilize a multi-meter. describe the law of magnetism. list the steps to fill out a lock out tag. Electrical Math Concepts demonstrate the use of English and Metric measurement. perform mathematical computations as they relate to electrical control activities. interpret various charts, graphs and drawings. generate ideas and design solutions to problems. explain the theory of ohm’s law. list basic terms, components and symbols. demonstrate the basic needs and usages of blueprint specifications. utilize a multi-meter. Basic Circuits Students will demonstrate knowledge of basic electrical circuitry. 4 Performance Objectives constructing, troubleshooting and recording the readings of a circuit. Students will select proper settings and ranges, interpret values indicated on digital multimeters (DMM). differentiate between alternating current and direct current and identify common applications for each. explain the difference between conductors and insulators. explain the difference between digital and analog meters. explain how voltage, current, and resistance are related to each other. calculate electrical values in series and parallel circuits. apply solderless terminals and wire nuts. properly remove insulation and make pigtail and device terminations. exhibit the ability to safely and correctly use electrical instruments to measure voltage and resistance. measure velocity, horsepower, revolutions per minute (rpm), amperage, circuitry, and voltage in units or parts to diagnose problems, using ammeters, voltmeters, wattmeters, and other testing devices. find the total amount of resistance in a series, parallel, and s series-parallel circuit. calculate, using Kirchoff’s Voltage Law, the voltage drop in series, parallel, and s series-parallel circuit. test faulty equipment to diagnose malfunctions using test equipment or software. 5 Industrial Electricity Skill Set Knowledge Objectives Performance Objectives WVEIS 1807 Electrical Basics Students will demonstrate knowledge of the applications of basic electrical theory. electrical symbols and interpretation of electrical diagrams. properly connecting common types of motors. Students will study blueprints, schematics, manuals, or other specifications to determine installation procedures. identify and use common electrical symbols on wiring diagrams. differentiate between power and control circuits on electrical diagrams. explain the operation of basic control circuits. define voltage, current, resistance, and power in electrical circuits. calculate voltage drop in a series circuit. calibrate equipment. test faulty equipment to diagnose malfunctions using test equipment. apply Ohms Law and the power formula to calculate electrical values in series and parallel circuits differentiate between alternating current and direct current, and common applications for each. explain the National Electric Code for grounding. explain the purpose and application of fuses and circuit breakers according to the NEC. identify section of NEC on installation of electric motors. compare and contrast AC/DC motors. explain the methods used to reverse rotation on motors. demonstrate how to connect a dual-voltage three-phase induction motor for operation, and reverse rotation. identify the types of electric motors commonly used in industrial applications. explain the purpose and application of an electrical coil. demonstrate the application of maintained and momentary switches to control loads. install ground leads and connect power cables to equipment, such as motors. identify components commonly used in power distribution systems. explain the application of transformers in power distribution systems. differentiate between single-phase, three-phase, and direct current power circuits. apply Ohms, Watts, and Kirchhoff’s laws. connect wires to circuit breakers, transformers, or other components. calibrate testing instruments and installed or repaired equipment to prescribed specifications. operate equipment to demonstrate proper use or to analyze malfunctions. maintain system logs or manuals to document testing or operation of equipment. 6 Rotating Devices and Control Circuitry Skill Set Knowledge Objectives Performance Objectives Students will demonstrate knowledge of wiring diagrams to construct motor control circuits. electrical symbols and interpretation of electrical diagrams. properly connecting common types of motors. Students will Skill Set Knowledge Objectives Performance Objectives WVEIS 1771 Control Circuitry study blueprints, schematics, manuals, or other specifications to determine installation procedures. identify and use common electrical symbols on wiring diagrams. differentiate between power and control circuits on electrical diagrams. remove and replace defective parts such as coil leads, carbon brushes, and wires, using soldering equipment. rewire electrical systems, and repair or replace electrical accessories. Motor Controls Students will demonstrate knowledge of relays and starters. automatic circuits. AC and DC motors. Students will explain the difference between manual and automatic circuits. identify the equipment and parts needed for automatic circuits. differentiate between power and control circuits on electrical diagrams. explain the operation of basic control circuits. list and identify motor and motor control symbols. explain purpose and uses of pilot devices. install various types of electronic and mechanical sensors and pilot devices. design and explain counter circuits. construct basic AC and DC circuits for manual and automatic controls. install jogging, plugging and reversing circuits. design and explain relays and relay circuits. install overload relays in control circuits. explain the difference between relay and magnetic starters. adjust various types of time delay relays. install, test, and troubleshoot various types of single-phase, and three-phase motors in a circuit. use a phase rotation meter. 7 Industrial and Commercial Wiring Skill Set Knowledge Objectives Performance Objectives Students will demonstrate knowledge of NEC requirements for raceways systems. conduit bending. Students will list NEC requirements for installation and construction of various conduit and raceway systems. plan layout and installation of electrical wiring, equipment, or fixtures, based on job specifications and local codes. place conduit, pipes, or tubing, inside designated partitions, walls, or other concealed areas, and pull insulated wires or cables through the conduit to complete circuits between boxes. Skill Set Knowledge Objectives Commercial Load Calculations and Configurations Students will demonstrate knowledge of Performance Objectives WVEIS 1765 Conduit and Raceways calculating commercial loads using NEC. single-phase and three-phase transformers. delta and wye configurations. Students will calculate the following: window loads; lighting loads; luminary loads, receptacle loads; general lighting loads. inspect electrical connections, wiring, relays, charging resistance boxes, and storage batteries, following wiring diagrams. connect wires to circuit breakers and transformers. identify safety precautions when working with transformers. compare various types of transformer connections. terminate dual-voltage transformers for high and low voltage operations. inspect electrical systems, equipment, or components to identify hazards, defects, or the need to adjust or repair. 8